Battery recycling is not just about waste management it’s about conserving resources, protecting the environment, and creating a more sustainable future. Here’s a closer look at how the recycling process works and why every used battery deserves a second life.

-

Collection and Transport

Used batteries are collected from various sources like automotive service centers, retail stores, battery dealers, and recycling drop-off points. These are then transported safely to certified recycling plants using proper handling techniques to prevent leaks or contamination.

-

Sorting and Disassembly

Once they reach the facility, batteries are sorted by chemistry type — such as lead-acid, lithium-ion, nickel-cadmium, and others. Each battery type has a unique structure and chemical composition, so it’s critical they are processed using the appropriate method. Disassembly is done carefully to separate internal components for further treatment.

-

Breaking and Separation

In this stage, machines break down the batteries into smaller parts.

- Acid inside is safely drained.

- Plastics float in water and are skimmed off.

- Heavy metals like lead sink to the bottom and are separated.

This separation process ensures maximum recovery of reusable materials with minimal environmental risk.

-

Component Processing

Each component is then treated and processed for reuse:

- Lead: Melted, purified, and recast for use in new batteries or other industrial products.

- Plastic: Cleaned and shredded into pellets, ready to be moulded into new battery casings or other plastic items.

- Acid: Neutralised using chemicals or converted into other useful compounds used in detergents, textiles, or fertilisers.

This step ensures that hazardous materials are neutralised and valuable components are reintroduced into the manufacturing cycle.

-

Reuse and Manufacturing

The final stage is all about closing the loop. All the recovered and purified materials lead, plastic, and neutralised acid are supplied back to manufacturers to make brand-new batteries. This circular system drastically reduces the demand for raw material mining and lowers the overall environmental footprint of battery production.

Why Battery Recycling Matters

Battery recycling isn’t just good practice it’s a critical part of environmental responsibility. Here’s why:

-

Saves Resources

Recycled materials reduce the need for raw mining of lead, zinc, and plastic — preserving natural resources for future generations.

-

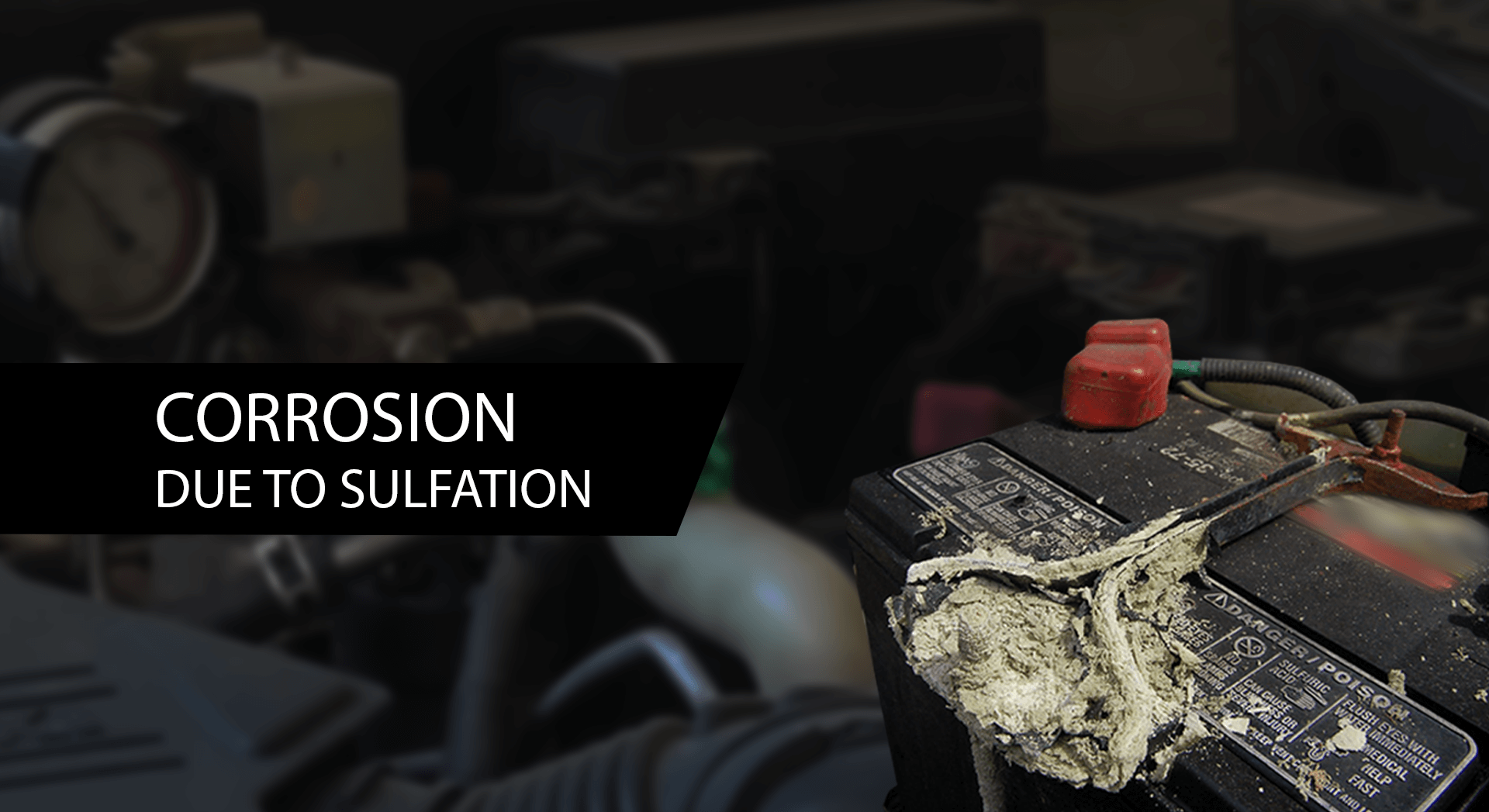

Puts Safety First

Proper disposal prevents toxic lead, sulfuric acid, and lithium from contaminating soil and water, protecting communities and ecosystems.

-

Lowers Energy Use

Recycling takes significantly less energy than extracting and processing virgin materials. It’s an energy-efficient solution to a growing problem.

-

Prevents Pollution

By keeping battery waste out of landfills and incinerators, recycling helps stop toxic leakage into the environment, safeguarding air, soil, and water.

-

Reduces Waste

Did you know that up to 99% of lead-acid batteries are recyclable? Recycling helps avoid landfill overload and maximises material recovery.

-

Supports Sustainability

Recycling supports a circular economy where products are reused, remade, and recycled reducing our dependency on finite resources.

Pro Tip

Recycle responsibly. One recycled battery saves more than just metal it protects health, conserves energy, and helps build a cleaner planet.