For commercial fleets in India, keeping trucks and heavy vehicles running smoothly is a top priority. While drivers and routes get most attention, the battery is often overlooked. A healthy battery is essential for starting the engine, powering electronics and supporting auxiliary systems. Regular battery checks can prevent costly breakdowns, improve efficiency and keep your fleet on schedule.

Early detection of problems

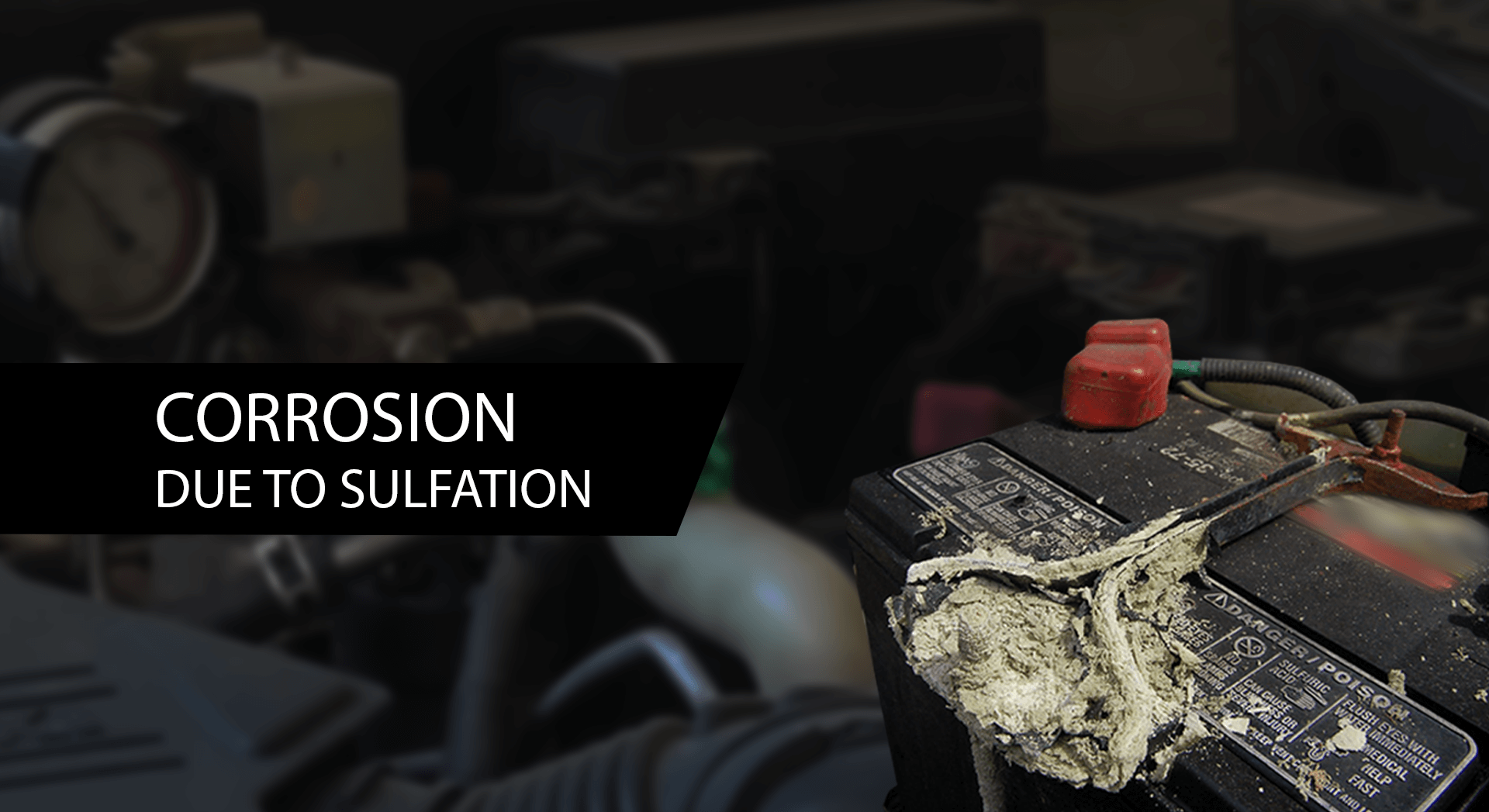

Checking batteries regularly helps identify small issues before they become major problems. Batteries can lose charge, develop corrosion or have loose connections over time. If these problems are detected early, they can be fixed before the vehicle fails on the road.

For example, a slight drop in voltage might indicate that a battery is weakening. By noticing this early, fleet managers can replace or service the battery before it causes a starting failure. Detecting problems early keeps trucks operational and reduces the risk of delays.

Safety assurance

Battery issues are not just inconvenient; they can be dangerous. A faulty battery can leak acid, overheat or even short-circuit, leading to fire hazards. Loose terminals or corroded connections increase the risk of sparks and damage to the electrical system.

Regular inspections ensure terminals are tight, connections are secure and the battery is clean and dry. This simple step protects drivers, cargo and the vehicle itself. For fleets transporting valuable goods or operating in busy city traffic, safety is a top priority and battery checks contribute directly to it.

Cost savings

Regular battery maintenance saves money in the long run. A failing battery can affect other components like the alternator or starter motor, leading to expensive repairs. Replacing a battery early, before it causes damage to connected systems, is far cheaper than dealing with a major breakdown.

Fleet managers can also avoid emergency roadside services or towing charges by keeping batteries in good condition. Also, scheduled inspections prevent operational losses due to downtime, enabling companies to save both money and time.

Extend battery life

Batteries in heavy-duty trucks face extreme conditions. Heat, cold, vibration and frequent short trips can all reduce a battery’s lifespan. Regular checks help maintain optimal battery health and extend its life.

Simple maintenance tasks, such as cleaning terminals, tightening connections and checking voltage, help keep the battery functioning efficiently. A well-maintained battery lasts longer, reducing the frequency of replacements and lowering overall maintenance costs for the fleet.

Improve fuel efficiency

A weak or poorly maintained battery forces the alternator to work harder to keep it charged. This extra load on the engine reduces fuel efficiency, meaning the truck consumes more diesel for the same distance.

By keeping batteries healthy, alternators operate more efficiently and the engine uses fuel more effectively. Over time, regular battery checks contribute to lower fuel costs, which is particularly important for fleets running long-haul routes across India.

Avoid unexpected downtime

Nothing disrupts fleet operations faster than a truck that won’t start. Unexpected battery failure can delay deliveries, impact schedules and cause revenue loss.

Regular inspections help identify batteries that are close to failing, allowing replacements or maintenance before the vehicle is stranded. Scheduled checks create predictability in fleet operations, ensuring that trucks are ready to go when needed and reducing the chances of unexpected downtime.

Keeping fleets running efficiently

Regular battery checks are not just a minor task; they are a key part of fleet management. They help detect problems early, ensure safety, save costs, extend battery life, improve fuel efficiency and prevent sudden breakdowns.

For commercial fleets in India, taking a proactive approach to battery maintenance keeps vehicles reliable, reduces operational headaches and supports smooth logistics. Simple steps, such as inspecting terminals, testing voltage and monitoring battery health, can make a significant difference in the long-term performance and efficiency of a fleet.

Maintaining batteries is a small investment of time that yields significant returns in terms of safety, cost savings and operational efficiency. A fleet that regularly checks its batteries stays on the road, on schedule and ready for every journey.

Common Reasons Truck Batteries Fail

Truck batteries can fail for several reasons. Understanding these helps prevent unexpected breakdowns.

- Temperature extremes: Cold weather slows the chemical reactions inside the battery, reducing its ability to produce power. Hot weather can cause battery fluid to evaporate, leading to corrosion and potential damage.

- Vibration and movement: Heavy-duty trucks travel on rough roads and endure long hauls. Continuous vibration can loosen battery connections or damage the battery casing. Loose terminals or damaged cables can stop the battery from delivering enough power to start the engine.

- Age and wear: Most truck batteries last three to five years, depending on usage and maintenance. Frequent short trips may prevent full recharging, shortening battery life. Older batteries are more prone to failure if not inspected regularly.

- Parasitic drain: Modern trucks have electronics like GPS units that draw power even when the engine is off. Over time, this continuous drain can reduce battery charge faster than expected.

Regularly checking the batteries can help address these issues before they lead to serious problems on the road.

Reliable Power with Tata Green Commercial Vehicle Batteries

For commercial fleets, every minute of downtime can mean lost revenue. Tata Green Batteries for commercial vehicles are built to deliver strong engine cranking, consistent performance and long life even under heavy-duty use. Designed to withstand harsh conditions, these batteries require very little maintenance while offering high durability.

Whether you manage trucks or other heavy vehicles, Tata Green Batteries provides a wide range of options to meet different power needs. Engineered for high performance and extended life, these cost-effective batteries help keep your fleet running smoothly, ensuring your business stays on the move without interruptions.

With Tata Green Batteries, fleet operators get reliable power and peace of mind on every journey.