Most industrial operations depend significantly on battery-powered equipment to enhance productivity and efficiency. However, despite careful handling and regular maintenance, the batteries that power industrial equipment may not last indefinitely, and like any other technology, they can experience issues.

Therefore, if you encounter any issues with industrial batteries, you will likely want to get the equipment operational again as quickly as possible. Fortunately, most of the time, these issues are minor and can be easily resolved. In this guide, we explore common industrial battery problems and provide troubleshooting tips that you can attempt yourself before calling a professional for repairs or servicing the batteries.

Battery issues

When you start industrial equipment, such as a forklift or drilling machine, it may sometimes fail to start. This could be because the battery is not functioning properly, or it may not be fully charged to power the machine, even if you recently charged it.

This is a minor issue that can be easily resolved. Therefore, in such a situation, it is advisable not to get frustrated. Instead, check the battery to ensure it is installed correctly. If so, the problem may lie within the system, or you may have made an error while charging.

Try charging the battery again, preferably with a different charger to ensure that both the charger and the battery are functioning properly. If this solution does not work, you may need to consult an expert.

The water level is low.

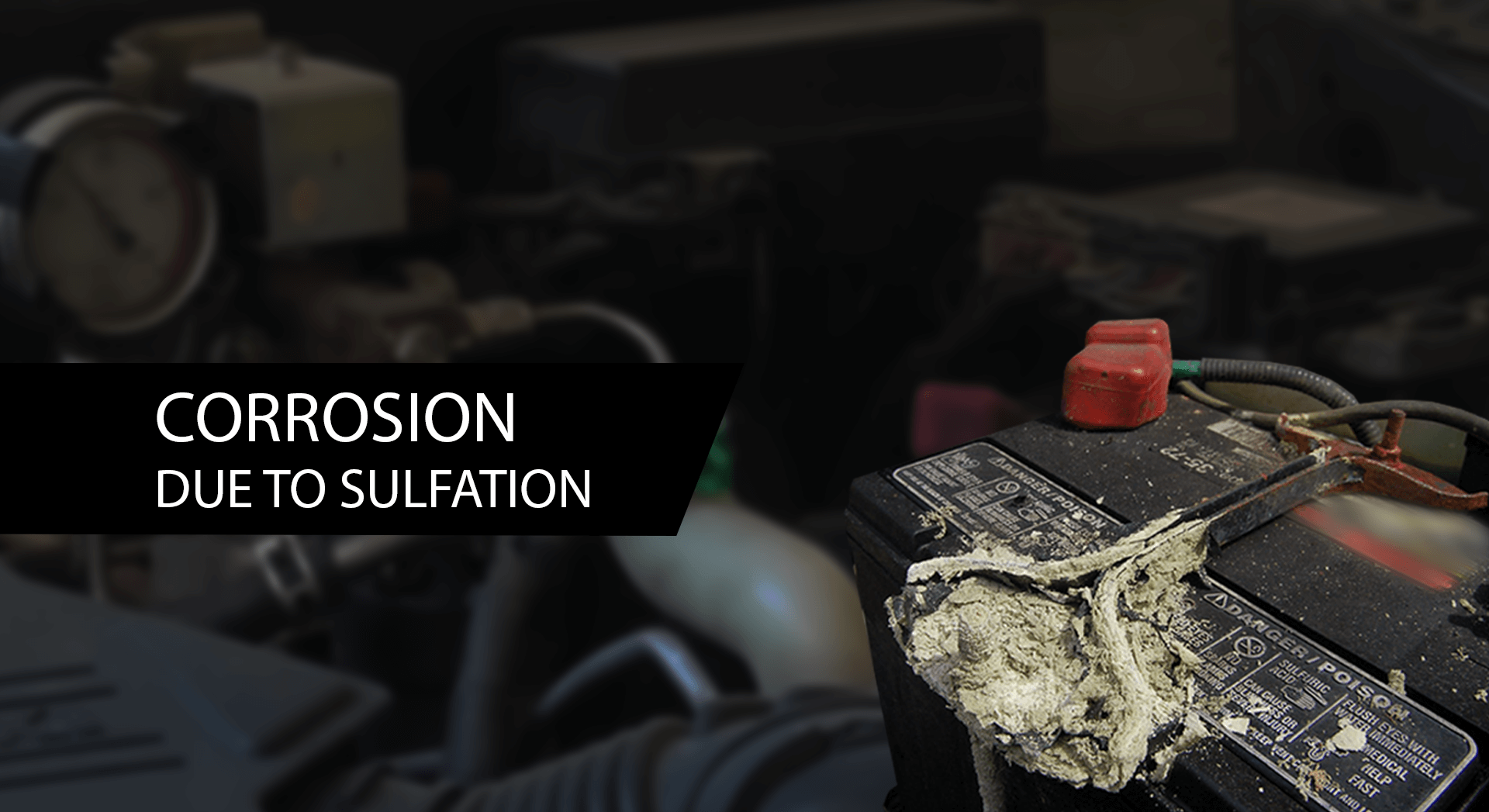

One of the most common industrial battery problems, aside from improper charging, is low water levels. Industrial batteries contain distilled water, and if the water level drops too low, the battery may overheat and fail to function efficiently. Sometimes, it may even fail completely.

If you encounter any issues starting the industrial equipment or if it is not functioning as efficiently as usual, check the battery to see if it is overheating. If it is, allow it to cool down first, and then check the water levels and refill to the required level.

It is always a good practice to periodically check the water level of the industrial battery. This ensures that the equipment runs efficiently and helps you avoid unnecessary downtime in operations.

Connectivity issues

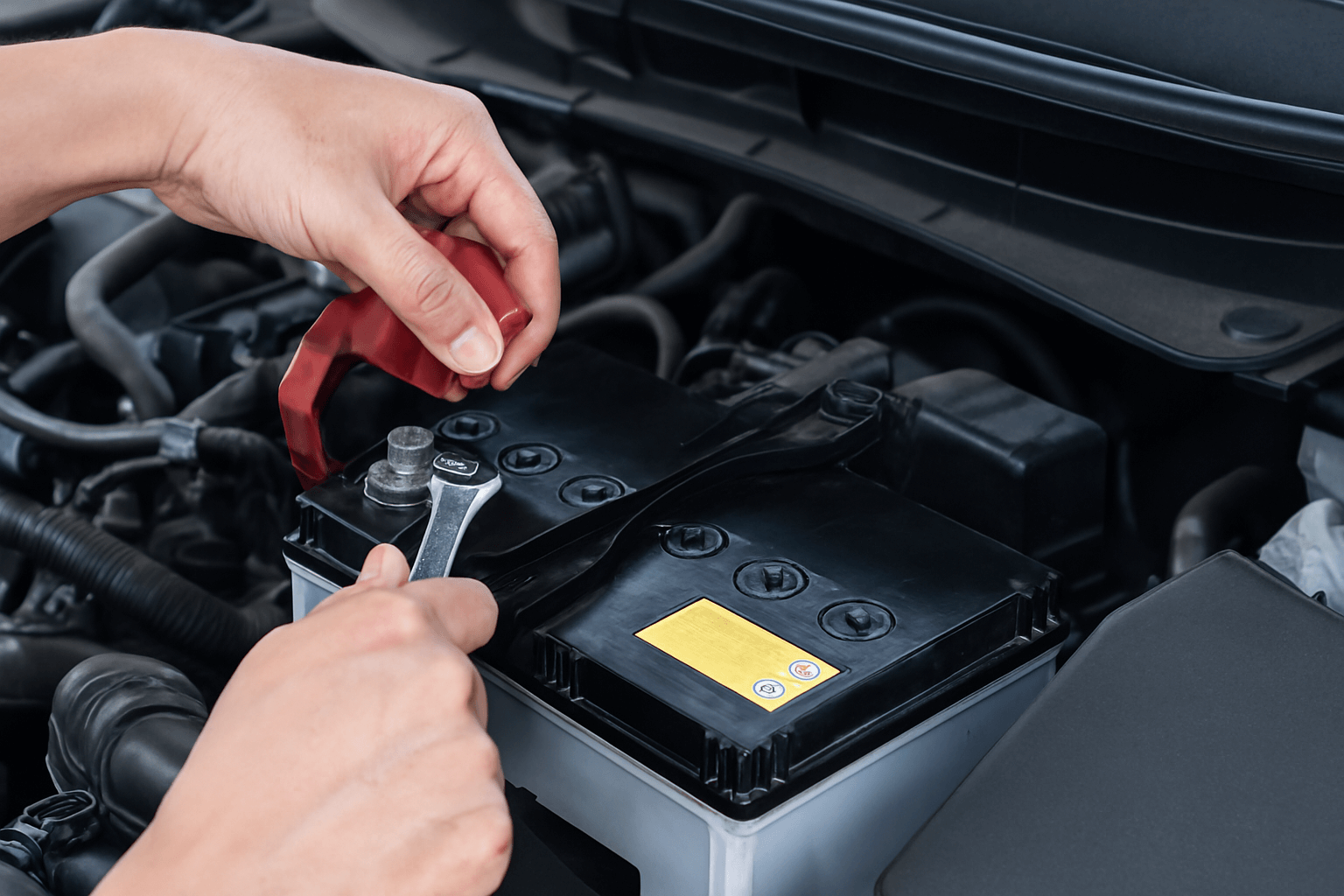

Another common issue that can arise with industrial batteries powering heavy machinery and other equipment is a connectivity problem. Sometimes, when charging the battery or replacing the old one, you might inadvertently fail to connect the battery correctly, leaving the cables attached to the battery loose.

If your equipment fails to start, before considering replacing or recharging the battery, it is advisable to check that the battery is securely connected and that all cables are firmly in place. Sometimes, the cables may loosen while the equipment is in operation.

If you notice any such issues, tighten the cables and ensure they are properly attached to the battery. After that, try restarting the equipment. The issue will likely be resolved. However, if the problem persists, it is best to consult an expert to examine the battery.

Test the charger

If you encounter any issues with industrial battery charging, the problem may not reside with the battery itself; instead, it could be related to the charger or the charging point. If the charger is malfunctioning or broken, it will prevent the battery from charging properly, or the battery may take longer than usual to charge fully.

If you notice that the industrial battery is not charging or is taking longer than usual to reach a full charge, check the charger. If there are clear signs of physical damage to the charger, replace it with the same or an equivalent model as needed.

However, if there are no visible signs of damage, try charging the battery with a different charger. If the battery operates normally, you can be confident that the problem is with the charger. Ensure you invest in a high-quality charger that is compatible with your specific battery type.

Conclusion

Industrial batteries older than five years may be prone to problems due to constant charging and wear and tear of the battery cells. Therefore, it is essential to be aware of when you are using the charger. If it is over five years old, it is advisable to replace it immediately, as it may start to fail, disrupt work, and potentially damage the equipment.

Battery charging problems are typically minor and can often be resolved by following a few simple troubleshooting steps. If you have tried everything and still can’t resolve the issue, it’s best to contact an expert for a thorough examination and solution.

Generally, it is advisable to use only top-quality industrial batteries. If you are looking to purchase a new battery or replace an old one, always choose one from a reputable manufacturer, such as Tata Green Batteries. This company is one of the leading manufacturers of industrial and automotive batteries worldwide, and its products are renowned for delivering exceptional performance even in the most demanding environments. Their designs ensure maximum efficiency, longevity, and reliability.

Visit the Tata Green Batteries website, compare the various models, and select the one that best suits your needs.